Cotton Dye Process: Regular vs Cationic

By Dean Schwartz (SWAG Master): If you follow our blog, you’ll notice we’ve started talking a lot about going green lately. And for good reason! There are SO many new, exciting ways to help our environment while maintaining the highest level of SWAG. Our last blog focused on UV water bottles that clean themselves. If you haven’t checked it out, you should definitely take the time to now because they are truly game-changing! But with so much focus on plastics, it’s important to remember there are other areas we’re focusing on to improve the health of our consumers and the environment. For instance, apparel products.

Apparel is a HUGE segment of the promotional product market – it includes basically any fabric item that you can put on. And the most common fabric found in apparel is cotton. But to make any cotton product pop with rich and vibrant colors, the fabric goes through a cotton dye process. It is through this process where we find the opportunity to push ourselves to be more environmentally friendly and get even greener. Let’s take a closer look at the cotton dye process and, in particular, cationic dyeing.

Cotton Dye Process: Regular vs Cationic

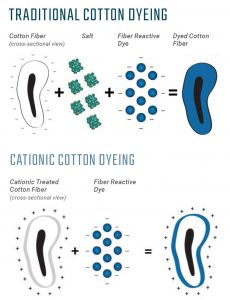

You might be saying, “cat-i-0-what?” Don’t worry, it’s easier than it sounds. Cationic actually refers to the cotton that is being dyed. Cationic cotton is cotton that has been chemically modified to possess a permanent “cationic” (or positive) charge. Why does this matter? Cotton naturally possesses a neutral or mildly negative charge when placed in water for the dyeing process. Many dyes used for cotton also possess a negative charge, though; and if you know anything about magnets, you know that common poles repel each other, meaning the dye won’t take to the fabric.

In the traditional process, extra chemicals (salt and alkali) are used to reverse the charge of the cotton fabric to positive. This ensures the dyes (negative charge) will bond to the fabric (positive charge). But when you’re using cationic cotton, the fabric already has a positive charge, which means you’ll need less water, energy, and chemicals to use during the dyeing process. A few quick facts:

- Regular cotton uses 80 tons of water compared to cationic, which only uses 24 tons.

- Regular cotton takes over 5 hours to dye compared to cationic cotton, which takes just 2 hours.

- Cationic dyeing uses 65% less energy than traditional cotton dyeing.

Going green isn’t always about the end product, sometimes it’s about the process. At SOBO we are committed to making our environment a healthier place for everyone. Want to know more about how we’re going green, or how you can make your SWAG more environmentally friendly? Give us a call at 888.752.0432 or email info@soboconcepts.com to find out more. Want to learn more about our bold fashion options? Click here! And remember to always #SWAGwithStyle!

Stay Hip to the Latest SWAG Trends - Sign Up For Our Newsletter!